Tue 11th Feb 2020 - Success Story from Kollmorgen - Optimising Bottle Production

Kollmorgen Solution Catapults PET Bottle Blow Molding Machine to Top Producer in the World

Challenge

ChallengeA major bottling operation in China needed to substantially increase output in order to ensure future success in a highly competitive market. For the company’s all-electric linear PET bottle blow molding machine, productivity depends on the ability to quickly index PET preforms into position and then remove the resulting molded bottles. The company engaged Kollmorgen motion experts in early 2019 to help minimize the machine’s indexing time.

Working closely with the customer’s machine design team, Kollmorgen engineers discovered that the indexing performance requirements were overtaxing the existing motor/drive solution. The motor wasn’t able to achieve the desired indexing speed without overheating. The drive was unable to supply the necessary acceleration current and would quickly go into current foldback, further limiting the power needed to meet the desired indexing time.

The only way to prevent overheating and foldback in the existing motor/drive combination was to increase the indexing time – slowing the machine down to the point that bottle-production targets could not be met. While a larger motor might have solved the problem, the machine design was fixed and did not provide the additional space that would be needed.

Solution

Achieving faster indexing times would require more acceleration torque and lower overall inertia. Kollmorgen worked closely with the customer to evaluate the indexing goals and to co-engineer a solution that would deliver the desired machine performance improvements. A Kollmorgen 2G Motion System supplied the additional power needed to dramatically decrease index time while occupying the same space as the prior motor and drive design.

Results

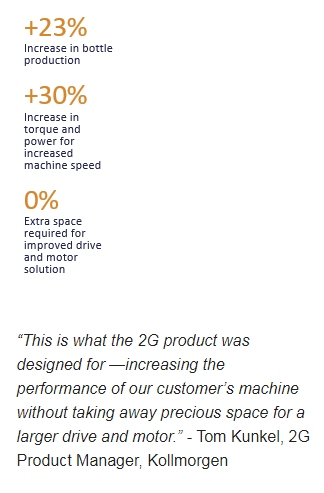

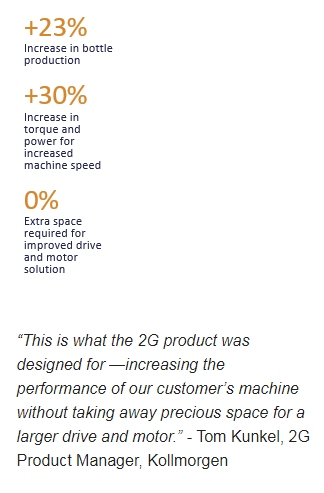

A simple, cost-effective upgrade to the 2G Motion System transformed the PET bottle blow molding machine and reinvigorated the customer’s business.

- Motor torque increased by 30% without an increase in size.

- Faster acceleration reduced the indexing time from 1.6 seconds to 1.3 seconds, a 23% improvement.

- No machine modifications were required to fit the AKM2G servo motor onto the existing motor mount, saving the customer design and documentation time.

- The machine now produces 156,000 bottles (600 ml) per hour, making it the #1 bottle producer in the world.

As a Gold Partner, Micromech are able to supply and provide expertise on

Kollmorgen products. Contact our sales team on

01376 333333 or

sales@micromech.co.uk for price and delivery or technical assistance.

Disclaimer

The use of this news article and images came with permission from Kollmorgen.

Challenge

Challenge